Surface Processing

- Home

- Technical skills

- Surface Processing

Super High Speed Resorbable Blast Media Coating

1. Super High Speed Resorbable Blast Media Coating

HAPTITE Implant is coated as Super High Speed Resorbable Blast Media Coating to solve the general problem of Plasma-Sprayed HA Coating at a room Temperature.

More than 95% of the surface of HAPTITE has a high crystalline phases to improve the durability of the peeling of an existing Plasma-Sprayed HA Coating technique can resolve the outstanding technology boasts.

Plasma-Sprayed which is commonly used HA coating technique is coated over 50um of thickness and HAPTITE Implant coating technique at room temperature is coated less than 2um of thickness which is the difference between them.

The problem of high-temperature coated Plasma

In the process of melts the surface of Implant a high temperature, Crystalline HA is changed in the amorphous and melt composition, so HA coating is peeling and the problems that are melting.

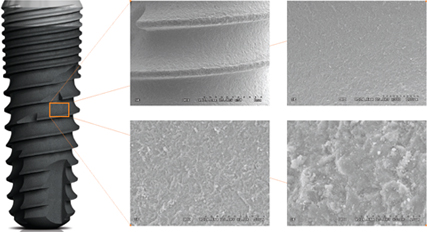

2. Surface Roughness and Surface Growth

-

Ra(μm) Surface

GrowthRBM 1.53 56.93 HAPTITE 1.87 363.63

The surface of HAPTITE with ultra-thin is over more than 20% and 600% higher than the surface roughness compared with RBM surfaced Implant, showing an advantages during the implantation of blood and osteoblast induced faster Osseointergration.

Dimensional Interactive Display

3. Analysis of the Elements on the surface with IC,ICP

| Sample | Al | Ca | Cu | Na | P | Si | Zn | F- | Cl- | No₂- | No₃- | No₄³- | No₄²- |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DENTIS | N.D | 0.90 | N.D | N.D | 0.40 | 0.01 | N.D | N.D | 0.03 | 0.02 | 0.04 | 2.66 | N.D |

| A | N.D | 2.43 | N.D | N.D | 1.00 | 0.05 | N.D | 0.12 | 0.14 | 0.06 | N.D | 1.29 | N.D |

| B | N.D | 19.17 | N.D | N.D | 15.84 | 0.12 | N.D | 0.09 | 0.07 | 0.05 | 0.03 | 23.16 | N.D |

After IC,ICP test during 1 hour eluted in distilled water, the elements by leaching from HA Coating Implant can be found as above.

In addition, Al, Na, F-, SO42- which are centralized management in DENTIS were not detected. On the ontrary, Cl-. No2- has been detected in a small quantity.

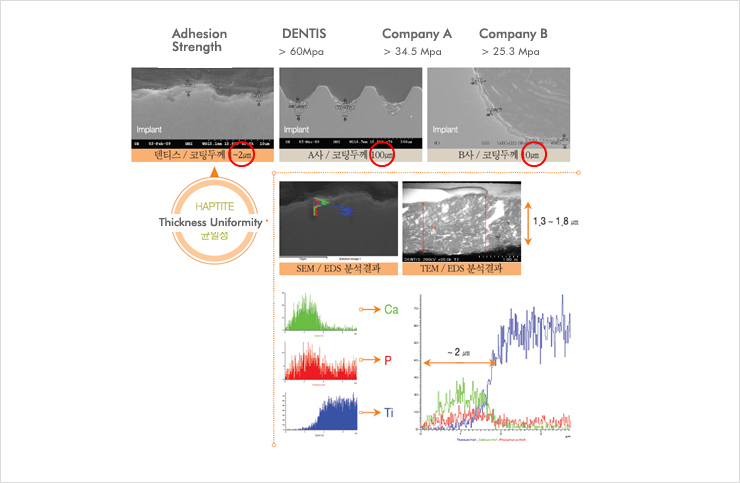

4. Coating adhesion strength and thickness uniformity of IC, ICP

5. High Crystalline HA

Crystalline HA Content of HAPTITE can be very high showed the graph of X-Ray diffraction of HAPTITE. (More than 95% of Crystalline HA).

HAPTITE made of high temperature coating method at room temperature is very low change of the higher amorphous component, which is not easily eliminated HA coating.

6. WETTABILITY

A angel was measured between the surface of implant and saline solution at the degree of 36.5 indicated that the angle for the surface of general Titanium of 32 and the angle for the surface of HAPTITE of 23.

The surface activity is high when the attached angle is getting a smaller to induce osteogenic for faster osseoinergration.

7. Attached Test For Osteoblasts

Titanum

HAPTITE

The number of osteoblasts adhered solid, which is well developed extracellular matrix

8. Experimental Comparison between RBM Implant and HAPTITE Implant of dogs

BIC(Bone Implant Contact): The length of contact with new bone screw / total length of the screw X100(%)

NBF(New Bone Formation): Threaded area of new bone formation / screws and the whole area X100(%)

ccording to animal test results, the osseointergration of HAPTITE is increased more than 16~42% compared With RBM treatment and especially, showing great results in the early bone formation.